Custom Forklift Truck Safety Signs to Satisfy Your Details Safety Needs

Custom Forklift Truck Safety Signs to Satisfy Your Details Safety Needs

Blog Article

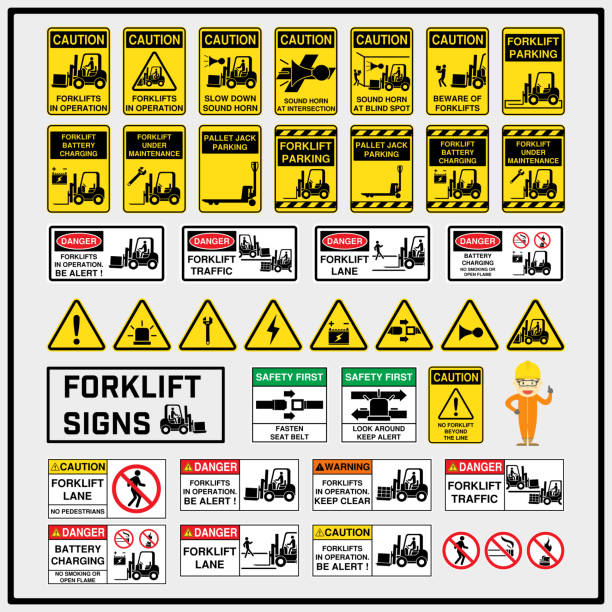

Ideal Practices for Displaying Forklift Vehicle Safety And Security Check In Industrial and Storage Facility Setups

The implementation of effective forklift truck security signage is vital in commercial and stockroom environments, where the danger of mishaps can dramatically influence both personnel and procedures. What details techniques can organizations adopt to ensure their safety signs absolutely serves its purpose?

Significance of Safety Signage

The significance of safety and security signs in settings where forklift vehicles run can not be overemphasized, as these indications play a vital function in stopping accidents and guaranteeing the security of personnel. Effective safety and security signs works as a vital communication tool, conveying vital details regarding potential threats related to forklift operations. This consists of warnings about pedestrian areas, speed limits, and designated forklift courses, which are crucial for preserving an organized and secure workplace.

Effectively displayed safety indicators can enhance situational recognition among employees, advising them of the dangers associated with their environments. They offer clear guidelines on risk-free practices, such as using suitable personal safety equipment (PPE) and sticking to functional guidelines. Moreover, safety and security signs adds to conformity with regulatory requirements, helping organizations stay clear of charges and promote a society of safety and security - Forklift Truck Safety Signs.

In enhancement to their preventive function, safety and security indications foster a sense of liability among workers. When employees know safety protocols and the possible consequences of overlooking them, they are most likely to take aggressive measures to secure themselves and their coworkers. Spending in high-grade safety signage is important for any kind of workplace where forklift trucks are in operation.

Key Exposure Elements

Efficient presence is paramount in making sure the security of both forklift operators and pedestrians in hectic work atmospheres. To accomplish this, numerous essential exposure elements should be thought about when developing and putting safety and security signs.

First, the dimension and typeface of the message on the indication play an essential duty. Bigger typefaces boost readability from a range, enabling individuals to rapidly comprehend the message. In addition, the usage of vibrant and clear fonts can substantially enhance legibility under various lights problems.

Efficient Positioning Strategies

Indication positioning significantly affects their efficiency in communicating security messages within forklift procedures. To optimize presence and comprehension, signs ought to be tactically positioned in locations where forklift task is widespread. Key locations include junctions, dead spots, and near loading and unloading zones, where operators and pedestrians communicate often.

Height is one more important aspect; indications ought to be placed at eye level to guarantee they are quickly seen by both forklift operators and ground personnel. Additionally, making use of contrasting shades and clear graphics will enhance presence, especially in low-light problems or high-traffic locations.

Think about the flow click to investigate of traffic when determining positioning. Signs need to be placed to assist operators securely have a peek here and efficiently via the workspace, decreasing the threat of mishaps. Regular evaluations ought to be performed to guarantee that indications remain unblocked by equipment or stock, as shifting designs can diminish their efficiency.

Incorporating responses from staff members relating to sign placement can additionally result in renovations. Engaging personnel in this process promotes a society of security and awareness, inevitably adding to a much more safe and secure workplace. By executing these reliable placement approaches, organizations can improve interaction and adherence to safety procedures.

Conformity With Rules

Making certain conformity with guidelines is crucial for keeping a secure workplace in forklift operations. Regulatory bodies such as the Occupational Safety and Health Management (OSHA) and the American National Requirement Institute (ANSI) develop guidelines that determine the correct usage of security signs. Adherence to these policies not just advertises security but likewise reduces the risk of fines and lawful obligations.

Forklift safety indicators need to be clearly noticeable, readable, and tactically placed according to governing needs. These indications should utilize standardized icons and shade codes to convey critical details successfully. Yellow shows caution, while red signals threat, making sure that employees can swiftly interpret the indicators in high-stress situations.

Organizations needs to carry out routine audits to validate that all security signs satisfies existing legal requirements. Keeping up with modifications in laws is additionally vital, as non-compliance can bring about considerable functional interruptions. By guaranteeing that forklift safety indications follow mandated guidelines, business cultivate a culture of safety understanding amongst employees, consequently boosting overall work environment safety and security and productivity. This commitment to conformity is an essential facet of a reliable safety and security monitoring program.

Regular Maintenance and Updates

Keeping and updating forklift safety indicators is critical for making sure that they stay reliable and pertinent in the workplace. Normal assessments ought to be conducted to examine the condition of safety and security signs, as direct exposure to extreme industrial settings can result in fading, damages, or obsolescence. Indications that are no more readable or that have obsolete information can significantly weaken safety procedures.

It is vital to develop a routine maintenance timetable that includes examining the visibility and clearness of all safety signage. Any kind of signs that are put on, harmed, or misaligned need to be immediately changed or repositioned Find Out More to keep their effectiveness. Furthermore, as laws and safety criteria evolve, it is important to upgrade signage to reflect present techniques and compliance needs.

Engaging workers in safety and security training sessions can also strengthen the relevance of maintaining and updating security indicators. This not just makes certain that every person knows the signs' significances yet additionally cultivates a culture of security within the work environment. By focusing on normal maintenance and updates, organizations can create a much safer environment and enhance the general effectiveness of their forklift safety and security signs.

Verdict

In conclusion, the implementation of best techniques for presenting forklift vehicle safety signs is crucial for boosting office safety and security in commercial and warehouse settings. By focusing on presence, using reliable positioning approaches, making certain conformity with laws, and dedicating to normal maintenance, organizations can significantly reduce the threat of crashes. Such procedures not only communicate hazards successfully however additionally foster a culture of safety that profits all staff members entailed in forklift procedures.

Report this page